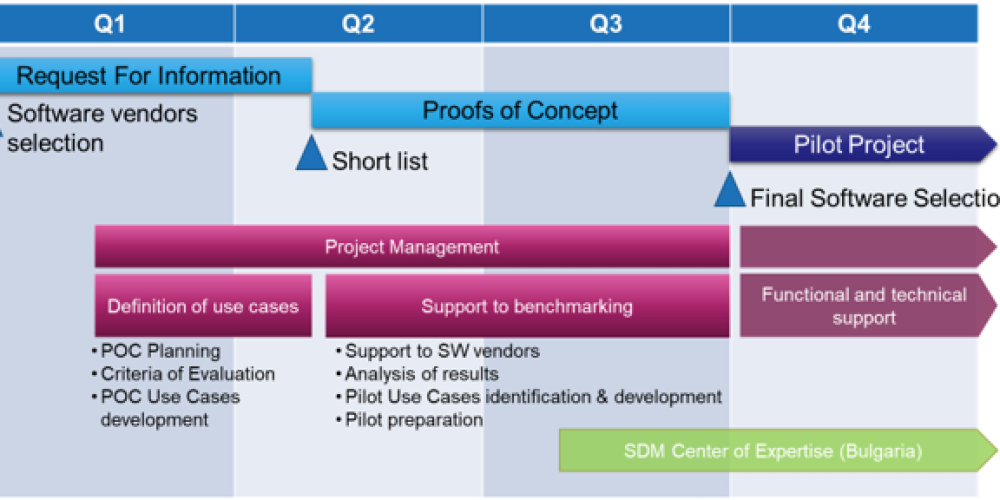

Our customer is a worldwide leading company designing and manufacturing high-tech industrial equipments to serve the electronics market. In the context of a ambitious program of Simulation Process & Data Management, Inensia has been selected as a trusted advisor during the software selection phase to formalize the business needs, define the selection criteria and prepare the business scenarios and data expected by the Software Vendors to implement some Proof Of Concepts. Thanks to Inensia expertise and SPDM knowledge, our customer has been able to select the right technology based on consistent criteria.

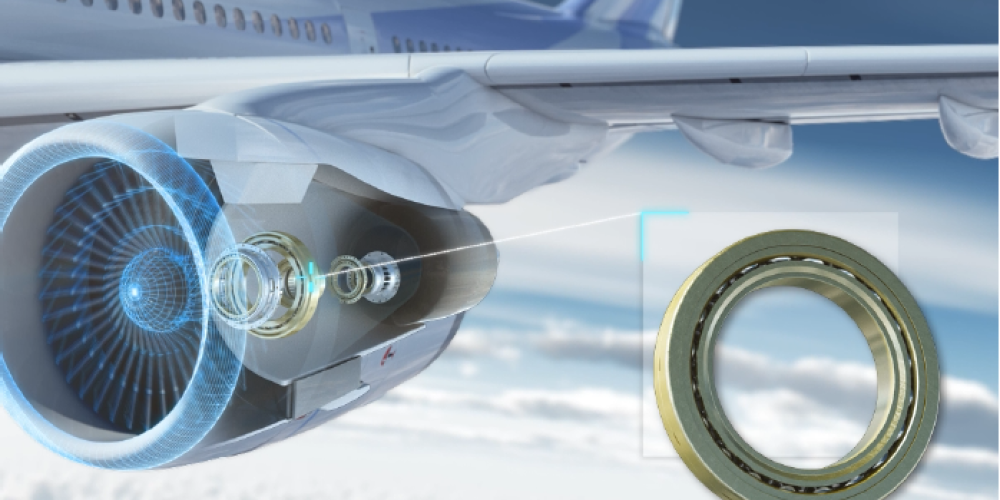

INENSIA designed and implemented an application to manage the Simulation Process & Data (SPDM) in the area of engine bearings, based on the Aras Innovator platform. Based on geometric parameters and flight condition data, the SPDM launches the process, run the simulation software at each step and manages input/output information up to the final key results.